PriceList for Spiral Feeder – Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King

PriceList for Spiral Feeder – Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King Detail:

Product parameters

| Model Item | YP-DL114 | YP-DL141 | YP-DL159 | YP-DL219 |

| Production Capacity | 3m³/ h | 5m³/ h | 7m³/ h | 12m³/ h |

| Pipe Diameter | φ114mm | φ141mm | φ159mm | φ219mm |

| Power Supply | 0,81kw | 1.56kw | 1.56kw | 2.2kw |

| Machine Structure | 304 stainless steel | |||

| Hopper Volume | 200L | |||

| Voltage | 220v/380v, 50hz/60hz | |||

| Inclined Angle | 45 degree for standard,30 or 60 degree can be customized | |||

| Discharging Height | 2200mm standard, others available | |||

| Hopper Type | round or square | |||

| Machine Weight | 130kg | 180kg | 230kg | 270kg |

Two motors are used for screw feeding and hopper vibration control respectively. Hopper amplitude can be adjusted according to material characteristics. The device can transport the material horizontally, inclinably or vertically, and the material can be fed in the sealed spiral tube. Look from the appearance of the equipment can be divided into U screw feeder and tube type screw feeder, from internal structure can be divided into shaft screw feeder and shaftless screw feeder, different styles have different functions, the customer can choose according to their own actual situation, the equipment is widely used in construction sites, feed mills, mines, or cooking oil and other industries.

The independent screw feeder is usually used combined with single bucket elevator and working platform.

Product features

1. Simple structure, easy to operate.

2. Small size, good sealing effect, can play a dustproof role.

3. Can be customized according to customer requirements.

4. The vibration and vibration range of the material box can be adjusted, the material box is designed independently, easy to take off.

5. 304 stainless steel sanitary buildings and food grade plastics.

6. Labor-saving conveyor, allowing a large number of material movement.

7. Reliable work, low energy consumption. Corrosion and wear resistance.

8. Requires low maintenance, easy to clean.

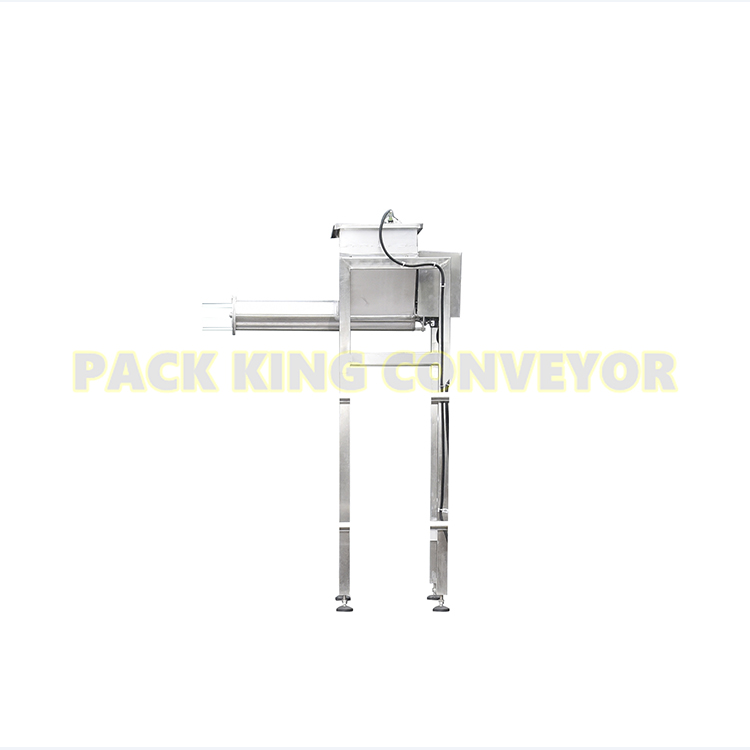

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for PriceList for Spiral Feeder – Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King , The product will supply to all over the world, such as: Greece, United Arab emirates, New Orleans, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.