Popular Design for Automatic Screw Feeder - Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King

Popular Design for Automatic Screw Feeder - Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King Detail:

Product parameters

| Model Item | YP-DL114 | YP-DL141 | YP-DL159 | YP-DL219 |

| Production Capacity | 3m³/ h | 5m³/ h | 7m³/ h | 12m³/ h |

| Pipe Diameter | φ114mm | φ141mm | φ159mm | φ219mm |

| Power Supply | 0,81kw | 1.56kw | 1.56kw | 2.2kw |

| Machine Structure | 304 stainless steel | |||

| Hopper Volume | 200L | |||

| Voltage | 220v/380v, 50hz/60hz | |||

| Inclined Angle | 45 degree for standard,30 or 60 degree can be customized | |||

| Discharging Height | 2200mm standard, others available | |||

| Hopper Type | round or square | |||

| Machine Weight | 130kg | 180kg | 230kg | 270kg |

Two motors are used for screw feeding and hopper vibration control respectively. Hopper amplitude can be adjusted according to material characteristics. The device can transport the material horizontally, inclinably or vertically, and the material can be fed in the sealed spiral tube. Look from the appearance of the equipment can be divided into U screw feeder and tube type screw feeder, from internal structure can be divided into shaft screw feeder and shaftless screw feeder, different styles have different functions, the customer can choose according to their own actual situation, the equipment is widely used in construction sites, feed mills, mines, or cooking oil and other industries.

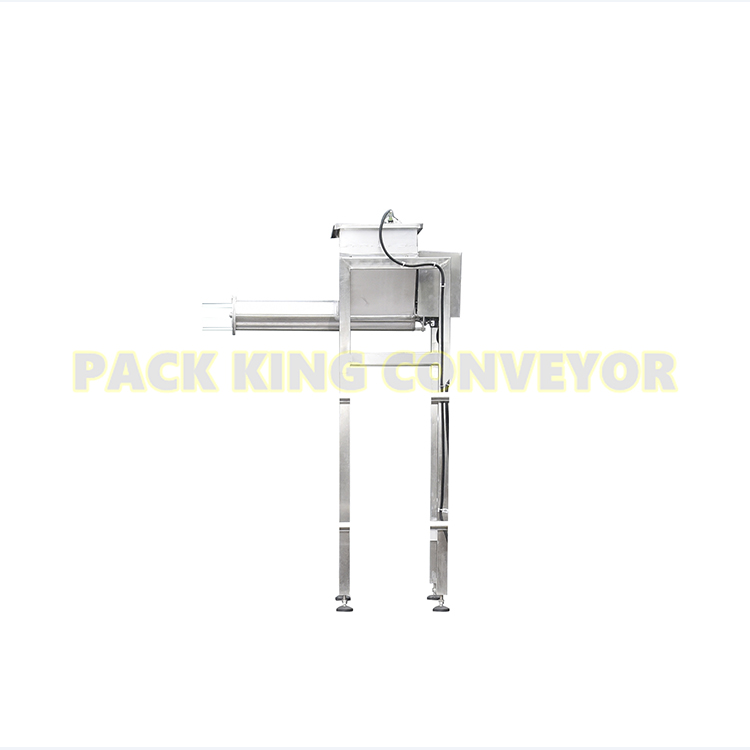

The independent screw feeder is usually used combined with single bucket elevator and working platform.

Product features

1. Simple structure, easy to operate.

2. Small size, good sealing effect, can play a dustproof role.

3. Can be customized according to customer requirements.

4. The vibration and vibration range of the material box can be adjusted, the material box is designed independently, easy to take off.

5. 304 stainless steel sanitary buildings and food grade plastics.

6. Labor-saving conveyor, allowing a large number of material movement.

7. Reliable work, low energy consumption. Corrosion and wear resistance.

8. Requires low maintenance, easy to clean.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Popular Design for Automatic Screw Feeder - Packing System Independent Auto Screw Feeder machine combined with bucket elevator – Pack King , The product will supply to all over the world, such as: Canada, Berlin, Sheffield, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.